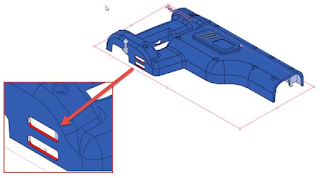

For the past few years DraftSight has introduced a lot of productivity enhancement tools, likewise in 2020 also they introduce automatically add & arrange dimensions. Dimension drawings automatically to save hours of time per drawing, improve consistency and reduce manual tedious tasks.

Steps:

1. Select All Entities > Right-Click > Dimension Bounding Box > Create

2. Type AUTODIMENSION > In the Properties Pane, select the entities for Horizontal Dimension scheme, Vertical Dimension scheme, Dimension Placements and Origin

3. At the bottom of the property pane > Preview and Apply.

4.

For Auto-Arrange Dimensions, Goto Annotate Tab > Select Auto Arrange, Alias –ARRANGEDIMESIONS > Specify the spacing value in the Dimension Palette and use the Thumbwheel to adjust the spacing of the dimensions.

For Auto-Arrange Dimensions, Goto Annotate Tab > Select Auto Arrange, Alias –ARRANGEDIMESIONS > Specify the spacing value in the Dimension Palette and use the Thumbwheel to adjust the spacing of the dimensions.

I believe that the above mentioned steps gives a better understanding of how to use the tool. Moreover, Auto-Arrange dimensions allow the user to save a lot of time while giving them direct control over dimension placement. They increases productivity by reducing a significant amount of time while inserting and adding dimensions to drawing.