CONFIGURATION PUBLISHER: SMART WAY TO DEVELOPING 3D MODEL

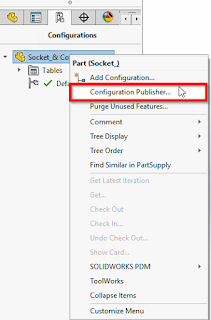

Solidworks configurations allow designers to maintain the different version of part and assembly in a single document. Three method for creating configurations: Manually Using configuration table Design table The fact is that capability is already available in SOLIDWORKS. In this article, we will see, how to use the configuration publisher to create the configuration. Once completing the assembly or model, this allows us to select the configuration we assemble using the same model attributes.To work with configuration Publisher, Microsoft Excel must be installed on our system. The follow the below steps in making the configuration Publisher. After creating desired configuration in part model, right click on the component name in configuration manger and select the configuration Publisher as shown below. CONFIGURATION PUBLISHER When we click the Configuration Publisher, the below Pop-up will be shown. If you didn...