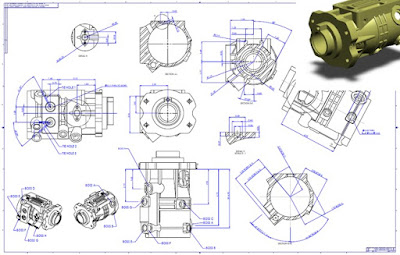

Detailed Drawings

- Automatic Drawing View creation and updation

- Dimensioning, Tolerancing and Annotations

- CAD Standards checking (Design Checker)—Compare your drawings to company standards

- Revision control—Control drawing revisions and graphically compare drawings to identify differences

- Unrivalled Drawing Creation by Drag and Drop of Views from View Palette.

- Draftsight for the benefit of 2d Users as Value Addition

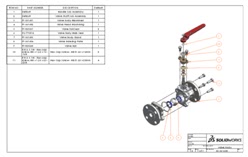

BOM / Ballooning

- Bill of Materials (BOM)—Automatically generate parts lists and cut lists to track material needs

- Automated Creation of Radial/Cylindrical Exploded Views - Significantly speed up the creation of exploded views

- Export BOM/BOQ directly to Excel which helps to integrate with ERP/MRP for material purchase & Cost estimation

3D Printer

- SOLIDWORKS enables printing directly to 3D printers, similar to how you would print a document to your office printer.

- SOLIDWORKS can also output .STL, a widely accepted format for 3D printing

- The 3MF and AMF formats provide more information about the model being printed.

- Bring life to your Product with enhanced Visualisation.

PaperLess - MBD

- Integrated drawingless manufacturing solution for SOLIDWORKS.

- Helps companies to define, organize, and publish 3D Product Manufacturing Information (PMI) including 3D model data in industry standard file formats such as eDrawings® and 3D PDF.

- MBD Streamline production, cut cycle time, reduces errors, and support industry standards such as Military-Standard-31000A, ASME Y14.41, ISO 16792, and DIN ISO 16792.

Go Paperless and Drawingless – SOLIDWORKS MBD.