We have been working with many Sheet Metal Fabricators for how quickly and cost-effectively they can create sheet

metal part designs and get the exact blank development for fabrication of the

components.

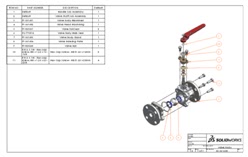

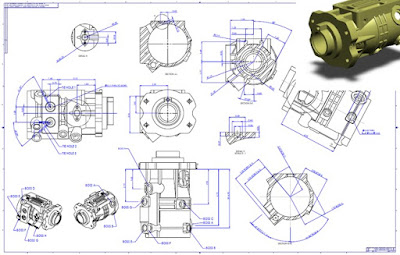

And also how to directly get the machine inputs from the CAD model using

SOLIDWORKS 3D Software.

Challenges faced by Sheet Metal

Fabrication Industry :

•

Manufacturing errors during Sheet Metal process like bending, punching, forming.

•

File conversion

like DXF /DWG for cutting and bending operation of Sheet Metal components using CNC, Laser cutting machines.

•

Requires entire

cut list for the different multibody sheet metals for fabrication.

• Estimation of

accurate blank development for manufacturing is tedious.

• Due to lack of

design communication lot of rework and scrap occurs.

• Want to make

blank development for forming tool.

SOLIDWORKS Solutions Proposed :

• Generate a

number of bends including loft bends, sketched bends and more.

• Sheet Metal

cultist provides the exact sizing like Length, Width, Thickness, Area etc for

different multibody Sheet Metal components .

• Take control of

bend allowances/bend reductions by using bend tables.

• Advanced Sheet Metal tool helps to find out exact Sheet Metal Blank area with bend

compensation using Flatten tool.

• Directly

convert it to DXF/DWG for the Sheet Metal CNC machining operation.

• Scraps can be

reduced or avoid by getting exact development length .

• Inbuilt forming tools are available in the Library and the blank development can be taken for it.

• Sheet Metal Costing tool helps to calculate the Material & Manufacturing cost Upfront in Design Stage.

• Sheet Metal Costing tool helps to calculate the Material & Manufacturing cost Upfront in Design Stage.

Benefits:

• Reduce

development cycle time

• Increase

product innovation

• Improved

quality and minimized design errors

• One stop

solution for changing needs

• Enhanced design

communications with existing & prospective customers

• Shortened time

required to make design changes by 90 percent.

SOLIDWORKS Customer

Testimonial:

“

What SOLIDWORKS solutions have allowed us to do is increase the speed of

development and design more complex solutions. That has enabled us to

significantly grow our business. We value the SolidWorks platform because it

gives us a real competitive advantage.”

Mr. Chris

Weiss - Vice

President of Engineering

THE KNAPHEIDE MANUFACTURING COMPANY

To Know More about Sheet Metal Fabrication Industry - Attend Our Live Seminar On Feb 2018.

Mail us to mktg@egs.co.in

For any Queries, Contact us @ 9445424704