Interference detection in SOLIDWORKS is a tool that helps find overlapping parts in an assembly. It ensures all components fit together correctly and prevents problems during manufacturing or assembly.

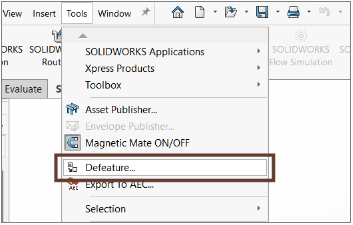

How to use in SOLIDWORKS:

Step: 1

➢ Open Your assembly in SOLIDWORKS

➢ Go to Evaluate Tab > Interference Detection.

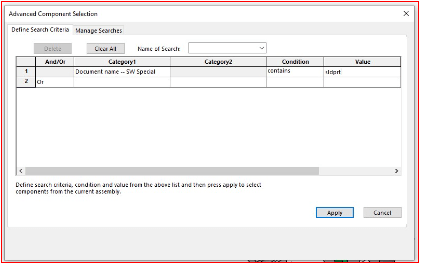

In Selection Components, the top-level assembly is selected by default, or we can manually select specific components

Exclude Components: Excludes specific components from the interference analysis.

Hide Excluded Components from View: Hides the excluded components in the graphics area.

➢ Show ignored interferences: Displays ignored interferences in the Results list.

➢ Treat subassemblies as components: Consider subassemblies as single entities, ignoring interferences between their internal components.

➢ Include surface bodies: Identifies interferences involving surface bodies but does not calculate the interference volume.

➢ Make interfering parts transparent: Displays interfering components as transparent for better visualization.

➢ Create fasteners folder: Groups interferences involving fasteners (e.g., nuts and bolts) into a separate folder named “Fasteners.”

➢ Ignore hidden bodies/components: Excludes interferences involving hidden components or bodies within multibody parts.

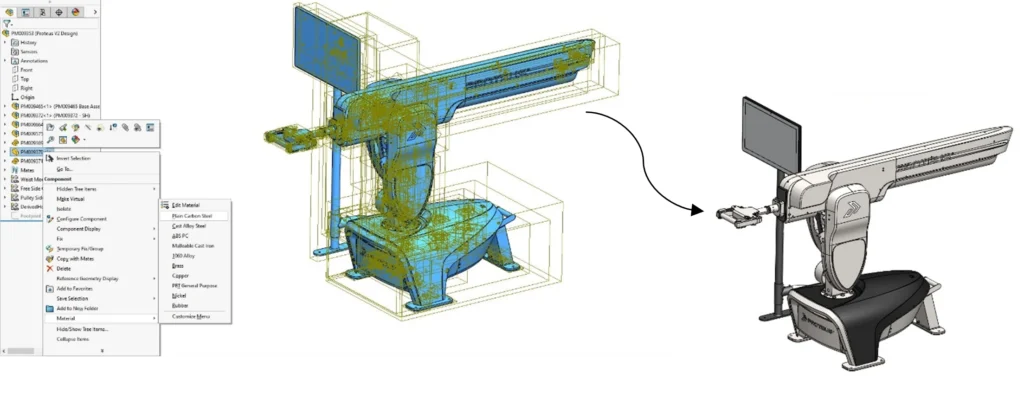

Once the option settings are checked, click “Calculate”.

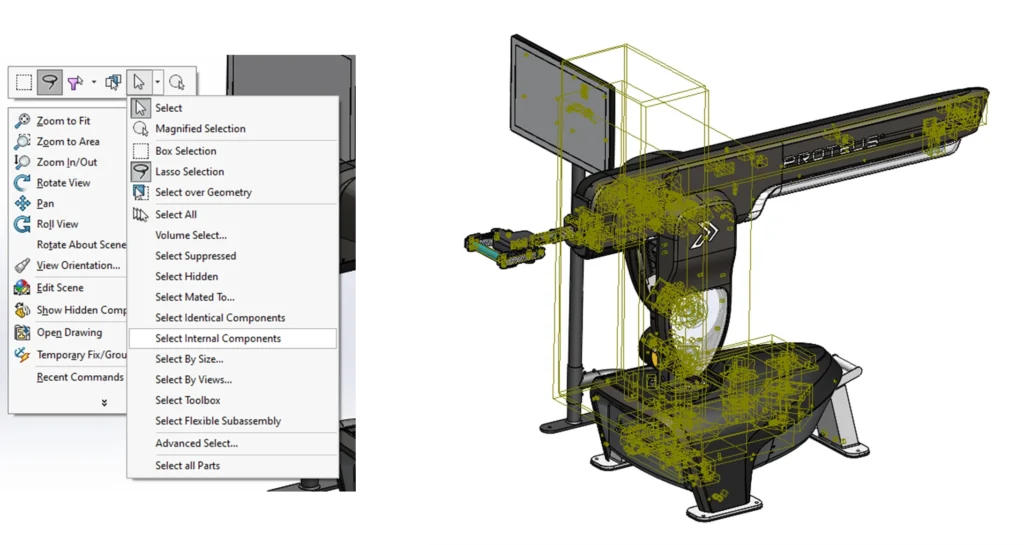

➢ Displays the detected interferences.

➢ Shows the volume of each interference listed.

➢ Selecting an interference in Results highlights it in red in the graphics area.

These options allow control over the display state of non-interfering components in the assembly.

Contact Us: Have questions or need assistance? Feel free to reach out!

Email: mktg@egs.co.in

Phone: +91 94454 24704