In SolidWorks, a weldment profile is a standard shape or cross-sectional geometry used to create weldment components. When designing welded structures, these profiles are commonly used to define structural members (such as beams, tubes, channels, angles, and so on).

Default File location for Weldment Profiles

SOLIDWORKS installed directory contains a default folder section. We discovered the location using the SOLIDWORKS system option, as sated below.

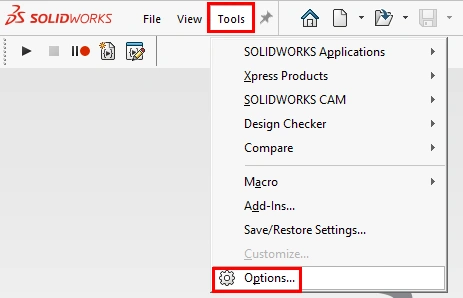

Go to Tools à Options à File Locations à Weldment Profile (Use the drop-down to go)

Default File location for Weldment profile:

C:\ProgramData\SOLIDWORKS\SOLIDWORKS 2025\weldment profiles.

If you want to maintain “Custom Weldment Profile” folder in above mentioned location, it will be shown in structural members. or If you maintain separately, you can added that location in system option.

Folder Structure for weldment

In SOLIDWORKS, we must comprehend that there are two possible file structure arrangements for welding profiles within the file explorer.

- An SLDLFP file with several sizes and configurations

- The SLDLFP file only depicts one size.

Create Custom Profiles

Step 1: Design your custom shape

Open new empty part and create sketching on any of the default planes with fully defined status.

Step 2: Save as to Library Feature Part

Weldment profile is a template. We need to save as Lib Feat Part. We must ensure that our sketch is accepted as a reference because this Library Feature Part file format differs slightly from saving a standard part file.

Note: Select ‘Sketch’ before save the sketch as lib feature.

While save as. sldlfp, the below pop-up appeared. Then process with ‘No’ to sketch converted into Library feature part file.

Notice that part icon in changed to Library feature book mark as shown in below.

Finally, we use this profile to create weldment structural components.

Author: Vinothkumar P

An Elite Application Engineer, with a strong emphasis on cultivating long-term relationships and driving customer success. And, plays a pivotal role in ensuring clients derive maximum value from their SOLIDWORKS solutions, specializing in personalized support during PDM implementation projects, combines years of industry experience to provide expert guidance. Recognized as a go-to expert in technical support and customer success, focuses on helping clients optimize their use of SOLIDWORKS CAD, SOLIDWORKS PDM (Product Data Management), and the robust 3DEXPERIENCE platform, enabling businesses to streamline their processes and enhance their product development workflows.

Contact Us: Have questions or need assistance? Feel free to reach out!

Email: mktg@egs.co.in

Phone: +91 94454 24704