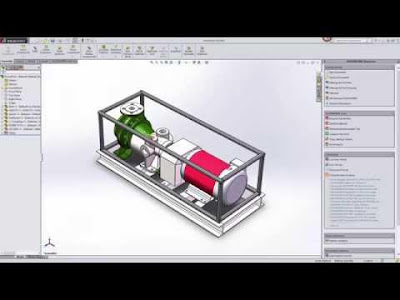

Introduction to SOLIDWORKS Visualize

SOLIDWORKS Visualize is a tool whoever like to present Products in high render photo realistic images and animations. In parallel, it will be more helpful to enter market very fast and leads to quick Return on Investment [ROI]

SOLIDWORKS Visualize- Boost up your Speed to Market

Objectives of SOLIDWORKS Visualize

SOLIDWORKS Visualize is a tool whoever like to present Products in high render photo realistic images and animations. In parallel, it will be more helpful to enter market very fast and leads to quick Return on Investment [ROI]

SOLIDWORKS Visualize- Boost up your Speed to Market

Objectives of SOLIDWORKS Visualize

- Visualize is simply known as CAMERA for CAD DATA

- CAD Live Update- Simultaneous Work in 3D CAD and Visualize

- Cloud Libraries- Appearance, Scenes, Backlights, Textures

- Positioning- Camera and Light as for real time environment

- Realistic High Quality Images

- Interior Panoramas

- 360 Degree Spin Animation

- Exterior VRs

Summarize

- Take Project to the Market at the earliest

- Improve high quality Brochures, Catalogues and Websites

- Make Customer/ Prospects satisfy before Prototype/ Manufacture

- Achieve Return on Investment [ROI] in Quick

- SOLIDWORKS Visualize is Easy, Fun and Fast