Posts

PRODUCE DEFECT FREE PLASTIC PARTS

- Get link

- X

- Other Apps

Introduction SOLIDWORKS Plastics is used for both part designers and mold designers. In this blog, you can get information on how this technology can help in creating and optimizing parts, single and multi cavity and family mold layouts. SOLIDWORKS Plastics SOLIDWORKS Plastics most useful for Injection Molding setup organization. Validate and visualize the melted Plastic Flow on the parts and molds. Improvise the part quality by predicting manufacturing defects in the initial stages of the design. Have alternate polymer material selection during the design phase using plastic simulation Create variations among your plastic designs and test virtually before the manufacturing stage. Steps involved in testing your Plastic Parts: Draft Analysis Meshing Applying Polymer (Material) Gate Location Run the Analysis Results Report Generation SOLIDWORKS Plastics contains vast material a...

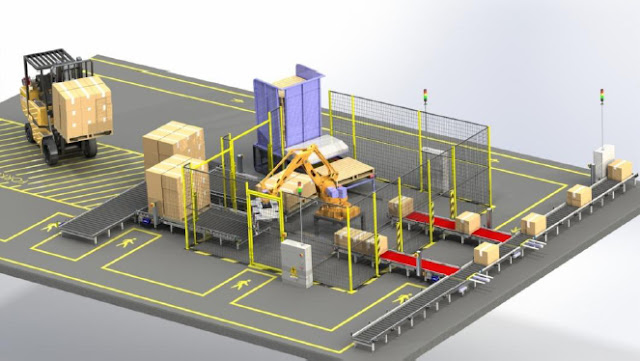

Ease your Material Handling Design with SOLIDWORKS

- Get link

- X

- Other Apps

Challenges faced in Design of Material Handling Systems Visualising Complex Designs Increased design cycle time Product quality and performance Design reuse and configurable Designs Increased Material costs & warranty costs How to address these challenges Transition from 2D to 3D and visualizing large assembly designs Reduce design cycle by Automating Design Process Improve product quality and performance by identifying hotspots Modular Design and Design interference Checks Weight reduction and load carrying capacity determination Ensure reliability and safety as per standards SOLIDWORKS Solutions in Action Solidworks Solutions boosts innovation to make Companies more profitable and more productive. Solidworks Simulation stands aside Design Team to Virtually test at early stages of design process Design Automation Tools like Driveworksxpress and Solidworks API improves performance and captures knowledge to be used continually. Design opti...

Leveraging Engineering Data across your entire Company

- Get link

- X

- Other Apps

Create Sheet Metal Swept Flanges "Hole" in a better Way

- Get link

- X

- Other Apps

One of the best sheet metal enhancements in SOLIDWORKS 2016 is the ability to add Cut Features to a Swept Flange and have those features map correctly to the Flat Pattern. Although the Swept Flange tool is a wonderful part of the Sheet Metal toolset, I have had many users comment about how frustrated they were that they could add Cut and Hole Features to their Swept Flanges and see them in their formed views but the hole features were missing in their Flat Pattern when it was time to send the part out to the Punch Press or Laser Cutter! SOLIDWORKS 2015 Sheet Metal Swept Flange Flat Pattern Above is a Sheet Metal part created in SOLIDWORKS 2015, the part is made using a Swept Flange and two Cut features. You can see when the part is flattened the two Cut Features do not propagate to the Flat Pattern and disappear from the view, this would usually result in having to add the Cut Features to the Flat Pattern separately which results in a potential loss in accuracy and adding valu...

Watch Out a New Tool in SOLIDWORKS 2016

- Get link

- X

- Other Apps

To ensure greater accuracy for digital simulation or to produce a 3D printed prototype, it’s often necessary to model the physical threads on shafts and holes, among many other features. To create a thread in previous versions of SOLIDWORKS, we had to manually create a profile and a helix for creating a swept cut. This process has now been automated with a new Thread tool in SOLIDWORKS 2016 . The new Thread tool allow us to create helical threads on cylindrical faces using profile sketches. Now, this feature is very flexible, allowing us to specify the start thread location, an offset, end conditions, the type, size, diameter, pitch and rotation angle, and even choose options like right-hand or left-hand thread. We can also create our own custom thread profiles like weldment profile. SOLIDWORKS allow us to store our custom thread profile as a library feature. The default location where these are saved can be modified at Tools > Options > System Options > File Locations . ...

OPTIMISING AIR FLOW INSIDE A LIVING ROOM

- Get link

- X

- Other Apps

Living Environment System A living system should maintain and balance the optimum room temperature. Heat balance in a living room is very important from the energy consumption perspective to influence the essential temperature parameters. The purpose of an air conditioner is to maintain a comfortable indoor environment. The comfort system is usually determined by a combination of three factors: Temperature Humidity Air distribution Air Conditioning Purpose: For this reason the main purpose of air conditioners are to: Control room temperatures (cooling/heating) Control room humidity levels (drying, humidifying) Optimise air flow (circulation, distribution) Clean Air (filtration) Introducing HVAC Flow Simulation: HVAC (Heating, Ventilation and Air Conditioning) is an integrated module...

MySolidWorks Professional Promotion Ending Soon

- Get link

- X

- Other Apps

MySolidWorks Professional adds tremendous value to thousands of SOLIDWORKS subscription customers worldwide with access to over 500 online training videos and SOLIDWORKS certification prep courses introducing new skills to help you become more productive. In addition to the existing training content, such as SOLIDWORKS Essentials, Advanced Part Modeling, Assembly Modeling, Electrical Design or Sheet Metal Design, we’ve recently added a few new topic areas including Simulation, Model-Based Definition (MBD), Enterprise PDM and Industrial Designer. Here is just a sample of the new training sessions you can take advantage of through MySolidWorks Professional: SOLIDWORKS Simulation – Discover the SOLIDWORKS Simulation product suite. Click here to explore the Simulation sessions . SOLIDWORKS MDB – This module is a SOLIDWORKS MBD overview. It covers the process of defining a model in 3D, capturing 3D Views and publishing a 3D PDF and eDrawings file. Click here t...

SOLIDWORKS 2016

- Get link

- X

- Other Apps

MAKE GREAT DESIGN HAPPEN SOLIDWORKS is about to release a new version of its flagship product in terms of innovation and improved functionalities with the roll-out of SOLIDWORKS 2016 by September 22, 2015. Solidworks 2016 comes with all the exciting new features and enhancements that are eagerly awaited by the customers. With SolidWorks 2016, user can focus on design and not anymore on software. This trustable & innovative solution chosen by millions of users worldwide has brought new features and enhancements for creating your innovative designs in an easier and faster way than ever before. CAD plays its vital role not only in design and development cycle, but also these CAD data can be leveraged to support the entire organization in achieving both technical and business goals. EGS India offers “THE GRAND SOLIDWORKS 2016 LAUNCH EVENT- INNOVATION DAY 2016” to personally show you, all of the enhanced features in SOLIDWORKS 2016. We are g...

Latest Trends In CAD Industries

- Get link

- X

- Other Apps

3D PRINTING Since the evolution of 3d printing technology, creation of complex models have become an easy task for many industries. It is now possible to print and create various sizes from an eagle's beak to a dream car. Solidworks offers 3D Printing solutions , so that we can bring our ideas to life as 3D printed prototypes , just like the way we print documents in our office printer. Solidworks can also output .STL and AMF Formats that provide more information about the model being printed. No post-processing is required to define data such as the position of your model relative to the selected 3D printer, orientation, color, materials, etc. MOBILE ACCESS - CAD Mobile access - CAD is a new emerging trend that reflects the mobile application technology and impact of seamless communication to handle 2D & 3D design data across your mobile devices anytime, anywhere. Design on the go just got better with eDrawings mobile app. Solidworks eDrawings enables...

Predicting Product's Mean Time between Failures - Simulation Webinar

- Get link

- X

- Other Apps