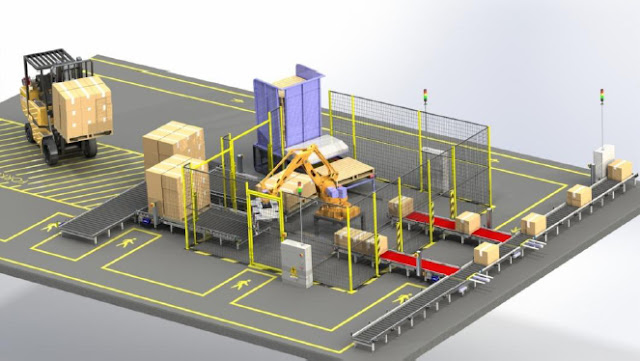

SOLIDWORKS 2016 SP 2.0

MAKE GREAT DESIGN HAPPEN SOLIDWORKS has launched a new Service pack update of SOLIDWORKS 2016. Check out, the all new SOLIDWORKS 2016 SP 2.0 Visit the link below to explore the SP 2.0 release document. http://files.solidworks.com/Supportfiles/Release_Notes/2016/English/relnotes.htm Contact us for more info on what’s New in SOLIDWORKS 2016: http://www.egsindia.com/solidworks-2016/index.html